DESCRIPTION

Make splicing easier and faster with this all-in-one fusion splicer. Never again will you have to juggle cleaver, hand strippers and alcohol bottles when you’re up a pole or working on a ladder. The KF4A FTTx Splicer has everything safely in one unit: a splicer, oven, a built-in heat stripper, precision cleaver and alcohol dispenser.

It is not just a splicer; it’s a splicing multi-tool. You can splice connectors directly to fibre, repair cables – and make your own pigtails and bespoke patch cords on site. There’s also a built-in power meter and visible source option, giving you the complete splicing platform to install FTTx networks.

The 4-motor active cladding alignment means losses are low and the built-in heat stripper also gives high strength splices. The Swift KF4A offers you all the flexibility, capability and productivity you’ll need.

KEY FEATURES

- Rotating blade life allows up to 77,000 cleaves

- Integrated 5 functions in one unit (stripping, cleaning, cleaving, splicing, protecting)

- The fusion splicer with All-In-One system provides the best workability onsite and in a limited work space

- No scratches on fibre by thermal stripping

- Compatible with Fusion Splice-on Connector (SOC) in accordance with the industry standards

- Ideal for Enterprise, Datacentres, Broadband and FTTH network applications

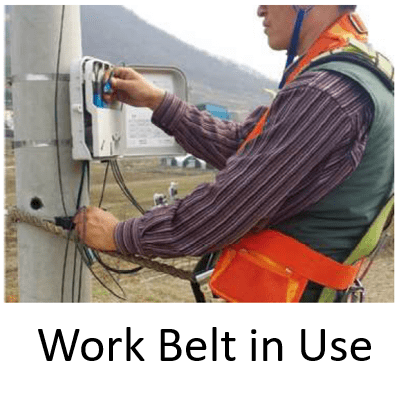

All-In-One Design:

All the tools you need on one device. The fibre stripper, alcohol dispenser and

cleaver are built into the splicer – and it’s light enough to wear with a work

harness. This means you won’t lose or drop anything when working at height. So

now you can focus on getting the job done quickly, professionally and safely.

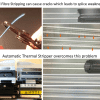

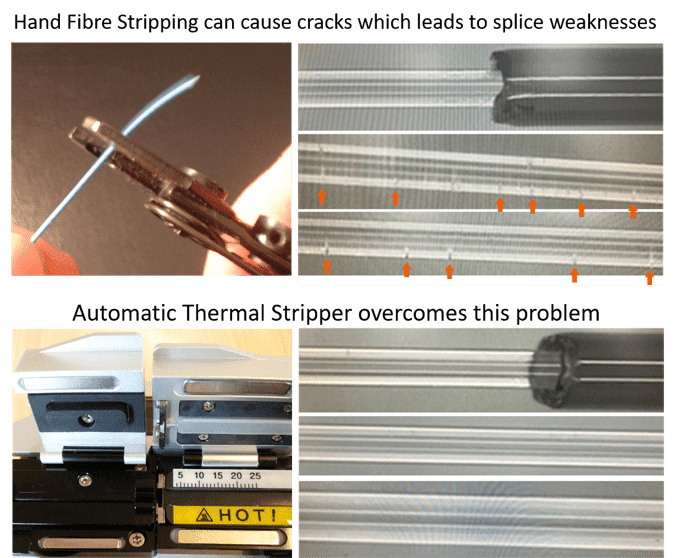

Heat Stripping:

There are many advantages of heat stripping the fibre. If you only use hand

strippers, there is a risk that the fibre will get damaged – which causes weak

splices and link failure. But, with the KF4A the built-in heat stripper softens and

rips the coating off the fibre without touching the glass. This method is normally

used in undersea joints, but the KF4A offers it as standard.

Cleaving:

The auto-rotating cleaver blade moves around after each cleave. This ensures

better cleaving while also reducing the need for maintenance. There’s a built-in

fibre chip collector too, ensuring you always have the safest working

environment possible.

Alcohol Dispenser:

A one-touch pump action dispenser is built into the splicer. It’s placed between

the stripper and cleaver – so it’s easy to refill.

Fibre Holders:

The KF4A FTTx Splicer comes fitted holders for 250 and 900 micron coated fibres.

The fibre holders mean you can transport the fibre quickly from stripper to cleaver to splice position faster and more easily than by hand. This makes the splicing process much quicker as the fibre only has to be positioned once. Consequently you no longer have to worry about strip lengths and cleave lengths.

Cable and SOC Holders:

There are also holders for cable and splice on connectors, allowing you to make

your own pigtails and bespoke patch cords. If you need a precise length (say 28-

metre SCPC to LCAPC patch cord), you have two options: call your supplier for a

7-day delivery; or make your own on-site in just 6 minutes!

View the KF4A Datasheet Here!

Active Alignment:

IPASS Active Clad-to-Clad alignment ensures low loss splices. On single-mode,

you’ll get 0.02dB, and on multi-mode you’ll get 0.01dB.

Resistance to Shock, Dust and Water:

With resistance to shock, water and dust – the KF4A FTTx splicer offers highly reliable and stable performance.

Datasheets

Hiring Options:

Hire the KF4A Splicer (All in One)(Opens in a new browser tab)

Hire Core Alignment Fusion Splicer (Opens in a new browser tab)