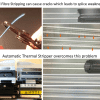

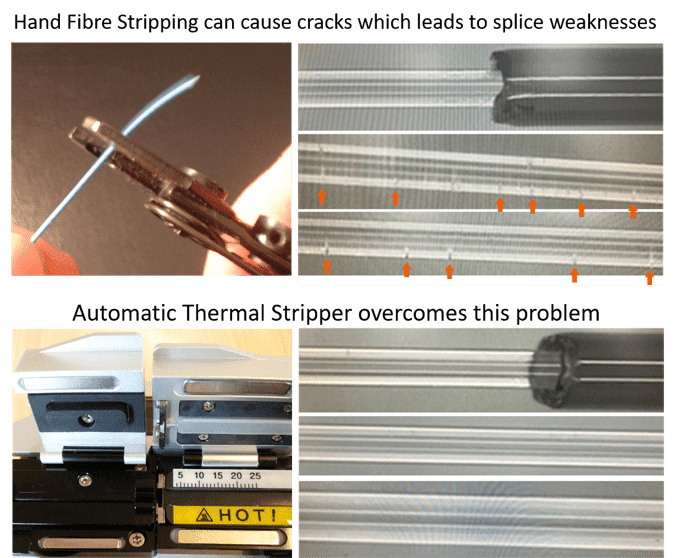

It may be that the way you strip the fibre coating is causing a problem. Most people use a hand tool to strip the coating from optical fibre. These tools have been tried and tested over many years but are these tools causing damage to the fibres?

Fibre splicing involves a five stage process of stripping the fibre, cleaning it, cleaving it, splicing and finally encapsulating the splice with a heatshrink protector. Research carried out by UCL-Swift, a leading manufacturer of fusion splicers has shown that hand stripping tools often damage fibres. It may be that you splice the fibre successfully, apply the heatshrink and during the heating process, a small nick in the fibre becomes a distinct crack and when you test the splice with a visible light source or OTDR you find that the fibre is broken.

The solution to this problem is a thermal stripping tool that heats and softens the coating then rips the coating of the fibre without touching the glass.

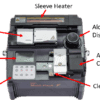

This system is used in several of the UCL-Swift splicers including the KF4A and K33A and it is also used in the Multipak-F. This combines a thermal stripper, precision fibre cleaver, alcohol dispenser, heatshrink oven, visible light source and power meter in one platform.

Swift Multi-Pack F can also be used to assemble Swift fusion Splice On Connectors (SOC) with any splicer from any manufacturer. The Swift Multi-Pack F satisfies users’ needs with its efficient and productive design. Furthermore, the unit delivers two other functions that make Splice On Connectors easy to terminate— the Optical Power Meter for loss measurement and the Visual Light Source for fault finding and component assessment in real time. (ALLINONE+)

| Stripping | |

| Stripped length | 250㎛ |

| Fibre Diameter | 0.25 ~ 0.9mm |

| Blade Lifetime | More than 100,000 |

| Motor Lifetime | 1,000,000 |

| Fibre Type | Single Fibre |

| Tensile Strength Test | More than 3Kgf |

| Heating Time | 0.1 ~ 15ec |

| Heating Temperature | 60 ~ 150℃ |

| Cleaning | |

| Method | Air-pump |

| Cleaning Spec. | 10ml / 24 times |

| Cleaning Liquid | Alcohol |

| Cleaver | |

| Cleaving Length | 7mm |

| Blade Lifetime | 50,000 |

| Sleeve Heating | |

| Temperature | 130 ~ 200℃ |

| Time | 10 ~ 150sec |

| Sleeve Length | 60mm |

| Fibre Type | 250, 900, 2 ~ 4 Connector 4Type(SC, FC, LC, ST) |

| Other Spec. | |

| Dimension | 145x137x98mm |

| Weight | 1.2kg |

| Power Meter | |

| Category | Description |

| Power range (dBm) | 10 to – 55 |

| Calibrated wavelengths (nm) | 850, 980, 1300, 1310, 1450, 1490, 1550, 1590, 1625 |

| Power uncertainty (dB) | ±5% |

| Resolution (dB) | 0.01 |

| Tone detection (Hz) | 270, 300, 1k, 2k |

| Display unit | dB/dBm/W |

| Warm-up time (sec) | 0 |

| Optical adapter type | SC (Standard) FC, ST (Optional) |

| Firmware upgrade | Enable |

| Operating temperature | -10°C to 50°C |

| Storage temperature | -40°C to 70°C |

| Relative humidity | 0% to 95% non-condensing |

| Visible Source | |

| Category | Description |

| Laser source | Class 3b laser diode |

| Laser wavelengths (nm) | 650nm (nominal) |

| Fibre compatibility | SM and MM |

| Output port | Universal adapter for connectors with 2.5mm ferrules |

| Output mode | CW or flashing(2~3 Hz) |

| Output power | >10mW into single mode fibre |

| Operating temperature | -10°C to 50°C |

| Storage temperature | -40°C to 70°C |

| Relative humidity | 0% to 95% non-condensing |