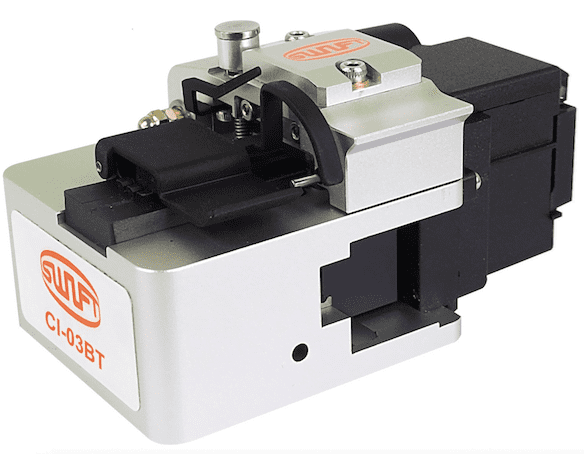

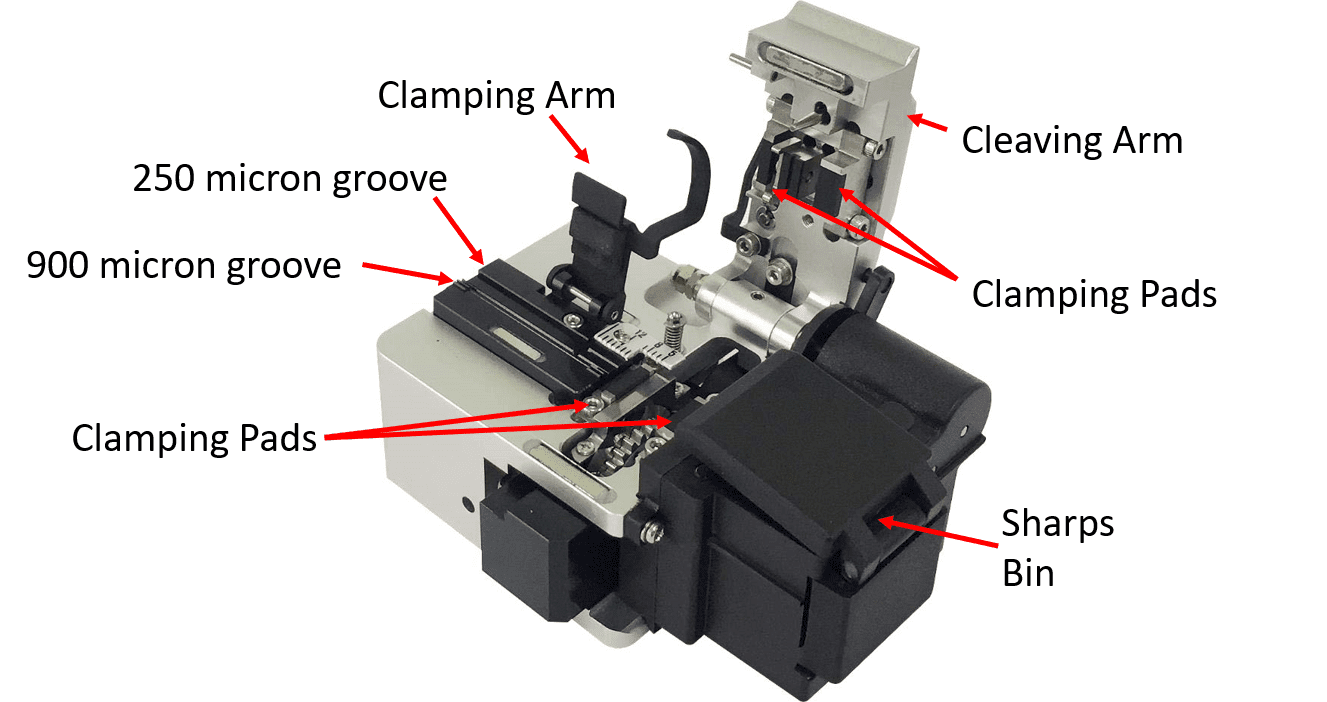

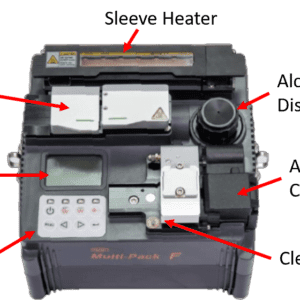

The CI-03 fibre cleaver includes a flexible clamping system to prevent vibration shock to the fibre during the cleaving process. This gives a dramatic quality improvement in the cleaved end face, core cracking, cleave angle and life span of the blade. It is engineered for high quality and consistency of cleaves.

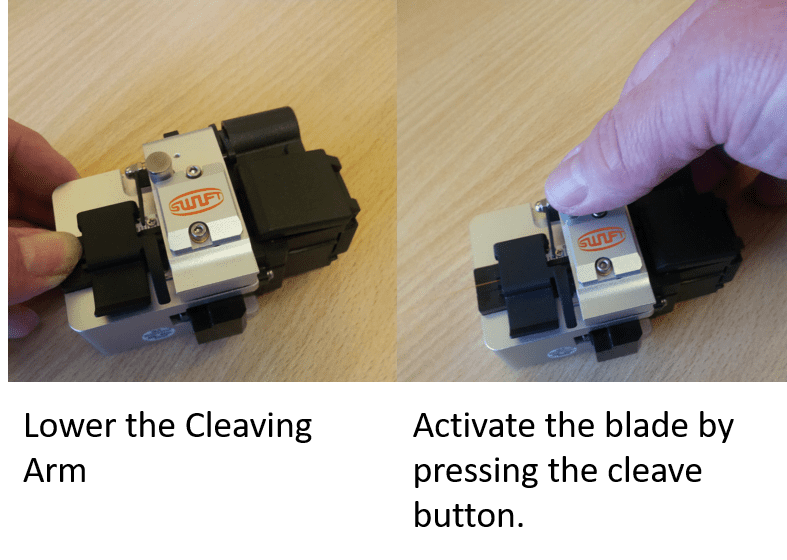

The CI-03 is a single action fibre cleaver which does not need the user to engage the blade prior to cleaving as with some other cleavers. You simply clamp the fibre into the vee-groove and close the cleaving arm. Simply the action of raising the arm engages the blade automatically ready for the next cleave.

Features

- Ideal for field Installation & Maintenance

- Compact design

- Produces the finest quality of cleaved end face using the unique Swift oil damper bearing system

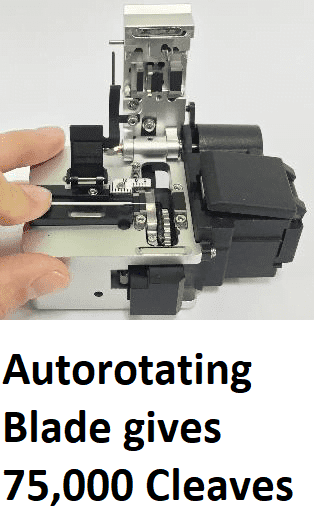

- Autorotating Blade improves the blade life span

- Up to 75,000 cleaves can be produced from one blade

- No crack in core is produced

- Single Operation cleaving mechanism

- Integrated Sharps Bin

- No blade adjustment is necessary

One of the main problems for standard fibre cleavers is that the blade needs to be rotated after the blade position has worn and has deteriorated. So the CI-03 fibre cleaver tackles this by rotating the blade after each cleave. Consequently, this leads to a massive increase in the blade longevity, improved cleaves and removes the need for blade adjustment. Too often with standard cleavers, operators have problems adjusting the blade but now the CI-03 eliminates this problem saving you time, effort and expense. In addition the CI-03 fibre cleaver uses a Swift Oil damper bearing system to produce the finest fibre end faces which have no cracks.

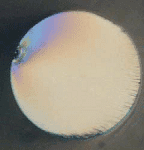

Image showing the end surface cleave which is flat with a discontinuity to the top left where the blade made contact with the fibre. The Autorotating blade and oil damper system means the CI-03 will always give consistent results.